Regardless of whether you are an amateur or a professional in the sewing business, when you start sewing, the question of using auxiliary equipment, other than the sewing machine, almost immediately arises. In particular, we are talking about a machine, the ability of which is to process the fabric from torsion. And not only, because when sewing products from elastane, its use is irreplaceable. However, fortunately, at the present time it is not a problem to purchase such equipment both in hardware stores and in highly specialized salons.

If you had to choose, overlock and carpetlock will certainly be presented to your attention. This is where the question arises, what is better to choose and how both devices differ from each other. Now we are faced with the task of figuring out: what is the difference between carpetlocks and overlocks?

main destination

Overlock, perhaps a familiar word to everyone, is a technique that, according to its purpose, is designed to overwrap fabric, and at the same time, during work, cuts off excess strips of matter. In professional sewing, it is simply an irreplaceable thing, and it is a great luxury to have one in the home arsenal for amateur sewing. After all, with its help you can achieve high-quality tailoring. It is suitable for overcasting various types of fabrics and textile fabrics.

A coverlock is also essentially the same overlock, only with advanced features. A coverlock can be called a combination of an overlock and a cover sewing machine. He can sweep almost all types of fabrics. And its main difference is that it easily copes with knitwear. That is, it is a feature through which it prevails over overlock.

Thanks to its special function, it can easily overwrap knitted fabric by applying a smooth, flat (cover-over) seam. This feature gives it a great advantage, since the use of elastic, knitted fabrics in the process of making various products is very common.

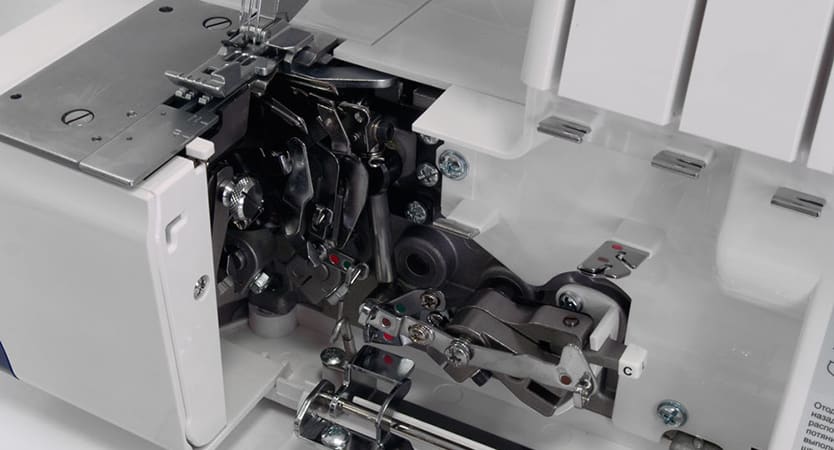

Structural differences

If we talk about external differences, then they, of course, take place in both devices. It:

- special (console) sleeve;

- number of loops.

These two details distinguish them from each other externally.

Cantilever compartment (sleeve)

In the overlock structure, this small part is almost absent. This is due to the fact that its function is reduced to processing fabrics, parts of products that are pre-prepared. That is, it boils down purely to overcasting finished elements.

The coverlock has a significantly larger cantilever arm area. This is dictated by the specifics of the application, because such devices are usually used by professionals, in particular, in specialized salons, factories that work with complex products.

Number of loops

This is the moment that eliminates the need for bobbin winding. The so-called progress in this compartment.

The overlock has two loops. When working, two, three or five threads can be involved at once. Which method you need in a particular case, you regulate yourself.

The coverlock is equipped with three loops at once, among which two actually perform the edge overcasting function. The coverlock is capable of performing the process using ten threads at once. However, in any case, you yourself choose the required amount. This process is regulated using a switch.

Functional differences

The overlocker is designed purely for overcasting, and does it very well. It is especially irreplaceable in the process of processing "loose" fabrics that can quickly spread out when trimmed.

The overlocker works on the principle of pressing the cut edge simultaneously with several threads and fast overcasting. This is a reliable way to overcast your garment the first time.

The carpetlock can do all this. He also successfully cope with fabrics with a loose structure, and not only. The main advantage of the device is its ability to perform a cover-up method of processing knitted fabric - a flat seam. And also a special way of processing successfully copes with finishing the neck and the like.

Cons of carpetlock

It would seem how such an effective device can have disadvantages. However, there is no perfect technique. Therefore, if there is an advantage in one thing, then in the other they will surely find at least insignificant, but disadvantages. Let's call them:

- High price. So, the cost of a carpetlock is really much higher than that of an overlock. Moreover, at this cost, you can buy two independent units of equipment, for example, an overlock and a cover-sewing machine, and they sometimes cost less than a carpet-lock.

- Complicated working principle. Despite the achievements, it is rather difficult to work on such a device. First you need to understand it well, and then work it out in practice. Especially work with jersey requires fairly quick maneuvers with gear shifting. It should be noted that even specialists in sewing technique recognize the principle of operation as complex.

- Great weight. Modern carpet locks can be improved by a number of the latest processes and mechanisms, due to which its weight will be quite large. All these additional functions are sometimes not even used in the process of work, and significantly complicate the process of setting up the device and operating.

We examined how overlocks differ from carpetlocks based on the main characteristics and can draw certain conclusions. It is impossible to say unequivocally which device is better on both. Probably, the choice should be based on the needs, capabilities and wishes for such a unit. The main thing is to correctly navigate the properties and basic functions of technology, and based on this, make the right choice. Your own right choice.