The Ariston washing machine stopped during washing, the sensors blink and the error F8 (F08) lights up on the display. This can happen when starting the system, in the middle of a cycle, before or after rinsing. What to do? What does F8 (F08) mean in the Ariston washing machine? How can I fix the problem myself? You will find answers to all these questions in this article.

Decoding the error

The manufacturer encrypted the heating error with the F8 (F08) code. This could indicate a malfunctioning heating element or damage to the temperature sensor and other problems.

With this error, the display will show the alphanumeric code symbol F8 (F08). If the washing machine does not have a display, the button lights will flash. The sequence of beeps will differ depending on the model:

- on Ariston Margherita cars, the sunroof lock lamp will light up continuously, with a short pause a series of 8 turn-on lamp signals will be repeated.

- model range AVL, AVSL will report a malfunction by flashing the indicator of the timer for delaying and blocking the hatch (key).

- on ARSL, ARXL series models, a number of program indicators will turn on completely, the spin lamp will be on continuously.

- Hotpoint-Ariston Aqualtis machines will have a “500” light on.

![]() See also - Washing machine Ariston gives error F9 (F09) - what does it mean?

See also - Washing machine Ariston gives error F9 (F09) - what does it mean?

Problems not requiring repair

Send contacts of heating element

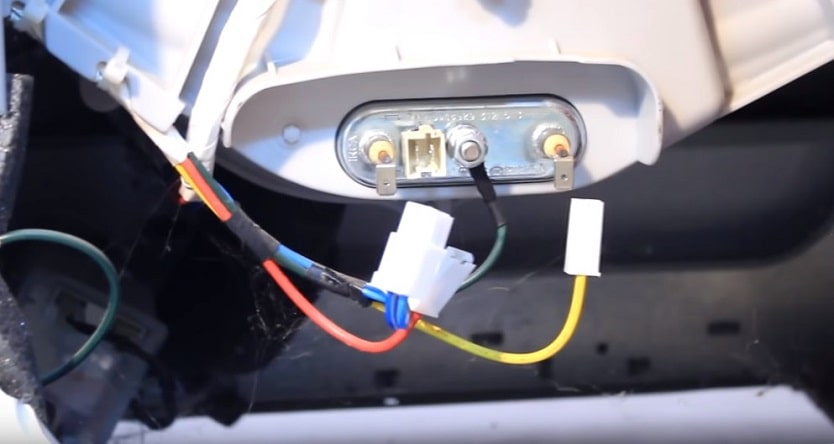

Poor electrical connection may be the cause of the problem. Three wires are connected to the heating element, each of them is connected to the heating element with a connector. If even one of the contacts is loose, loosened or fell off, this will cause the machine to fail.

To eliminate this problem, first of all, you must disconnect the power cable from the mains. Then remove the rear panel of the machine, behind which the contact terminals of the heating element are located and carefully correct the detached connector. After that, replace the removed cover and check the operation of the unit.

Failure in the control board

To restore normal operation, sometimes it is enough to reboot the control system. It is necessary to remove the cable plug from the socket for a while (5-10 minutes). If the fault is caused by a failure of the Control Unit, normal operation will resume after restarting.

High indoor humidity

Installing a washing machine in rooms with high humidity affects many of its elements. Traces of corrosion may appear on the housing, and condensation formed on the electrical contacts will lead to errors in operation.

To avoid such malfunctions, the machine should be installed in a dry ventilated area with adequate ventilation. Bathrooms tend to have a high moisture content and are more likely to malfunction. Therefore, it is better to install the unit in other rooms, for example, in the kitchen or in the closet.

Malfunctions in the heating circuit

Defective heating element

Heating element problems are a common cause of error F8 (F08).Under the influence of water and washing powder, solid deposits appear on the heating element. While trying to warm up the scale layer, the heating element is exposed to high currents and burns out. TEN failure a voltage surge in the electrical network can also serve.

If the F8 (F08) error appears while the washing machine is running, then you can determine the malfunction by placing your palm on the loading compartment door. Water with a temperature above 40 degrees will heat the glass.

In order to prevent the formation of scale, it is recommended to carry out cleaning the car with citric acid... Removing solid deposits will help increase the life of the heating element and prevent it from overheating. For this, about half a glass of citric acid is poured into an empty drum and the spin mode is turned on. After the end of the wash cycle, the scale will go down the drain together with the water.

Broken thermostat (temperature sensor)

The thermostat serves to regulate and maintain the set temperature. Sensor breakage is determined by the following features:

- despite the temperature set by the mode, the water heats up to a boil.

- the temperature of the walls of the housing of the unit itself rises.

One of three types of thermostat is installed on washing machines, different in design, but performing one function:

- bimetallic

- thermistor

- gas-filled

To determine the state of the thermostat, it must be removed and checked with a multimeter the resistance at the contacts. This will require opening the machine case, and each of the three types of sensor has its own mounting characteristics, this must be taken into account.

A defective thermostat cannot be restored; it must be replaced with a new one. The operation of the washing machine with a broken temperature sensor will lead to the combustion of the heating element, so such a repair should not be delayed.

Defective surge protector, wiring or contacts

The noise filter is out of order

To protect the electronic systems, a noise filter is installed in the washing machine. With strong voltage fluctuations, this part can fail. If a breakdown occurs, you will have to look for a new protection device. Noise filter defective detected by checking with a multimeter and visual inspection. If burnt contacts are found or a burning smell is present, then the cause of the error is clear and replacement is required.

Damaged wiring or pins

A common cause of malfunctions is faults in the electrical wiring of the washing machine. The contacts of the heating element and electrical circuits are oxidized under the influence of moisture. Damage to internal wiring leads to a short circuit and breakdown to the machine body.

A careful inspection of all wires and connections will help determine the problem. If an area with damaged insulation is found, it is necessary to restore it with electrical tape or heat shrink. Burnt contacts should be cleaned, and badly damaged ones should be replaced.

Broken water level sensor

This sensor (pressure switch) controls the amount of water, its level in the machine and is responsible for draining the liquid. Failure of the level sensor is determined by the following features:

- lack or excess of water when filling the machine.

- complete absence of water during washing.

- continuous collection of water followed by draining.

- the machine skips rinsing modes.

To check the serviceability of the sensor, it is necessary, after turning off the power, to remove the rear panel of the machine body and disconnect all fasteners of the pressure switch. After that, remove it and check the contacts with a multimeter. Also, make sure that the sensor tube is not clogged.

Faulty pressure switch will require replacement, the procedure for installing a new device will be the reverse of removal.

Defective control board

The control board is responsible for the functioning of all electronic systems of the washing machine, engine, heating element, etc. The main reasons for the failure of the control module:

- voltage drops in the network and, as a result, short circuit of the electronic components of the board.

- disconnecting the machine from the network without first pressing the shutdown button.

- exposure to high humidity in the room.

First of all, you should inspect the module. To do this, remove the control panel with buttons, release the retaining latches and disconnect all electrical connectors. Control board repair, in the event of a malfunction, is to find and replace damaged parts. This requires certain skills and ability to handle a soldering iron.

The control board is a very expensive device, so a qualified technician should carry out repair work.

See also:

- 10 best ATLANT washing machines according to customer reviews

- 10 best built-in washing machines

- 10 best washing machines under 15,000 rubles according to customer reviews

- 10 best washing machines under 25,000 rubles according to customer reviews

- 13 best washing machines from 40,000 to 50,000 rubles according to customer reviews